How Energy-efficient is the Rotary Retort Compared to Traditional Static Retort Machines?

In the food processing industry, energy efficiency has become one of the most crucial factors in determining the overall performance and sustainability of equipment. Among the most widely used thermal sterilization systems, the rotary retort has drawn increasing attention for its superior heating uniformity, shorter processing times, and lower energy consumption compared to traditional static retorts. But how exactly does a rotary retort machine achieve this improved efficiency, and what makes it stand out from conventional systems? Let’s take a closer look.

1. Understanding Rotary Retort Technology

A rotary retort is a type of food retort machine that incorporates a rotating drum mechanism during the sterilization process. Unlike static retorts—where the product remains stationary—the rotary system continuously rotates containers, such as pouches, cans, or bottles, within the pressurized chamber. This movement promotes even heat distribution, faster heat penetration, and consistent product quality.

The continuous rotation minimizes cold spots inside the product, ensuring that all portions reach the target sterilization temperature more quickly. As a result, rotary retort sterilization can achieve the same level of microbial inactivation as static methods but in less time and with less energy input.

2. Energy Efficiency Through Uniform Heat Transfer

One of the key advantages of a rotary retort autoclave is its efficient heat transfer capability. Because of the gentle and uniform agitation, heat is distributed evenly throughout the product, reducing the need for prolonged heating cycles. In static systems, achieving uniform temperature often requires extended processing times to ensure the coldest spot in each container is adequately sterilized—wasting both time and energy.

Studies have shown that rotary retort sterilization can reduce cycle times by up to 20–40%, depending on the product type and packaging. This means less steam usage, reduced cooling water demand, and lower overall energy consumption per batch. The result is a more sustainable and cost-effective sterilization process that benefits both manufacturers and the environment.

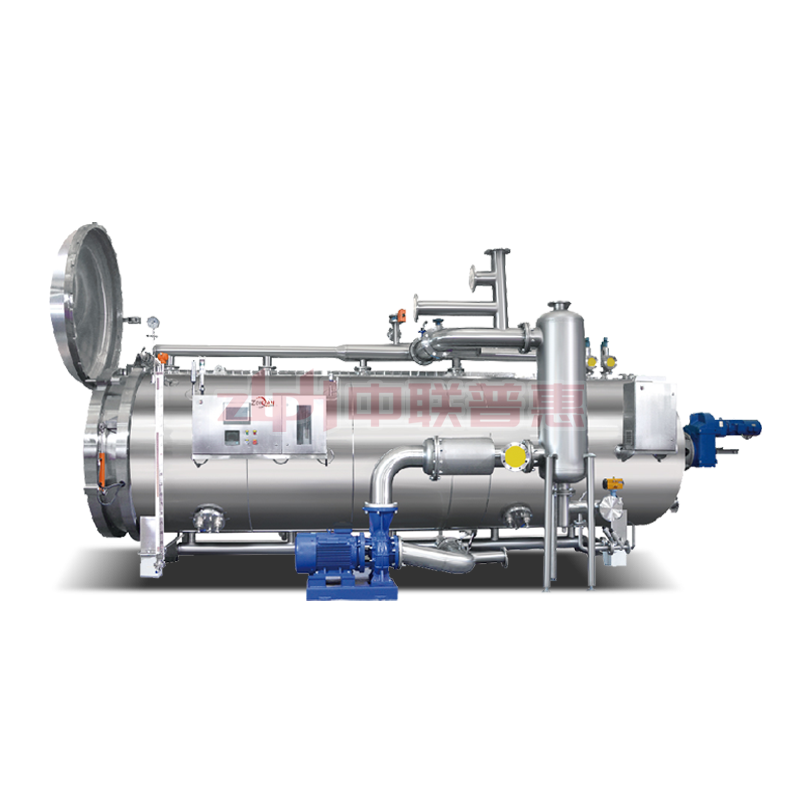

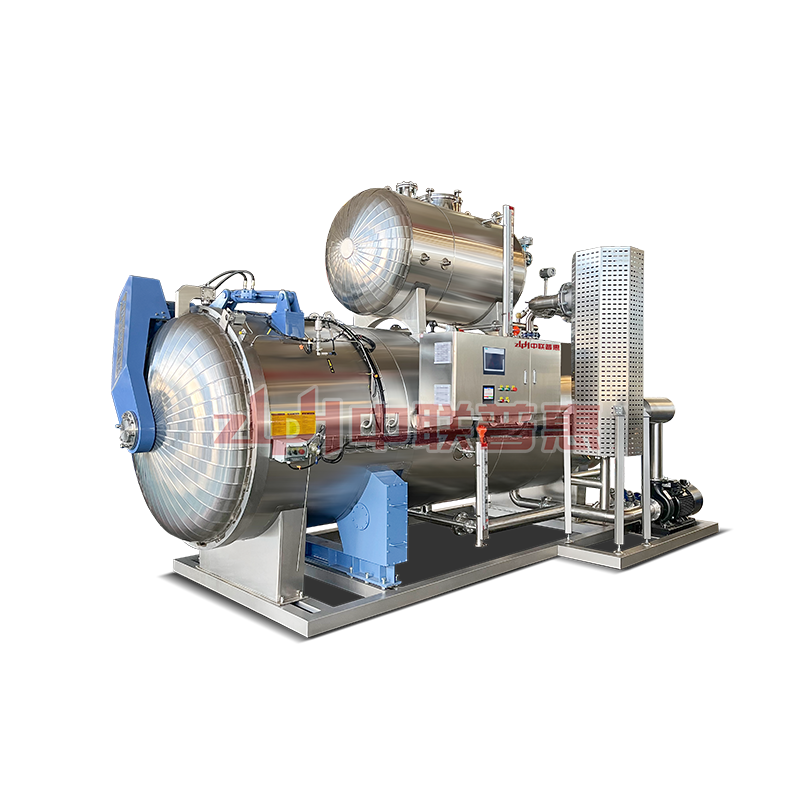

rotary retort sterilization

rotary retort machine

rotary retort autoclave

3. Reduced Processing Time and Product Loss

A rotary retort machine not only consumes less energy but also improves product quality. Shorter sterilization times help preserve food texture, flavor, and nutrients, especially in heat-sensitive products. In contrast, static retorts often expose food to longer heating periods, leading to overcooking or degradation of sensitive ingredients.

Because rotary retort sterilization achieves faster and more uniform temperature rise, manufacturers can maintain consistent quality with fewer rejected products. Reduced waste and energy savings together contribute to a lower overall cost per production cycle.

4. Smart Control Systems for Energy Optimization

ZLPH rotary retort autoclave systems are equipped with advanced digital control panels, automatic rotation speed adjustments, and precision temperature regulation. These intelligent systems monitor the entire sterilization process, ensuring optimal use of steam and water. In many cases, the automation helps identify areas where energy can be further conserved, such as minimizing steam venting and optimizing cooling water flow.

Static retorts, by contrast, tend to rely on longer, less precise heating phases, often resulting in unnecessary energy expenditure. The high degree of automation and feedback control in rotary retort machines significantly boosts operational efficiency and reduces human error.

5. Overall Energy and Cost Comparison

When comparing the total energy usage between rotary and static systems, the rotary retort sterilization consistently outperforms traditional setups. By cutting cycle times and improving heat transfer, rotary retort machine can lower steam and electricity consumption by up to 30% per batch. Over time, these savings translate into substantial cost reductions and a smaller carbon footprint for food processors.

The ZLPH rotary retort machine represents a major advancement in sterilization technology. Through efficient agitation, precise temperature control, and faster cycle times, rotary retort sterilization offers superior energy efficiency compared to static systems. As energy costs continue to rise and sustainability becomes more critical, investing in a rotary retort autoclave is not only an operational improvement but also a strategic step toward a greener and more competitive food production future.

food retort machine

rotary retort machine

rotary retort autoclave